UPVC which are known as Unplasticized Polyvinyl Chloride ball valves which are commonly used in various industries and plumbing applications due to their durability, chemical resistance, robustness, and affordability. What should a buyer look for before buying UPVC Ball Valve from the manufacturer. As a leading expert in the domain, we are providing some of the most important and specific details and various other significant factors which will help you in making a right buying decision about UPVC Ball Valves. So let’s get started.

UPVC Ball Valve Manufacturer In Ahmedabad, India

We are counted as one of the largest UPVC Ball Valve Manufacturers in Gujarat, India. This UPVC Ball Valves are a form of robust, long-lasting, and high quality products which are used for many different applications which are mentioned above in the points.

We are very well aware of the technicalities involved in producing superior quality UPVC Ball Valve products that can be used for a variety of purposes or applications because we have made a name for itself over the years and as UPVC Ball Valve suppliers we create them for the clients with keeping their demand and customizations in our mind.

We are manufacturing following type of UPVC Valves including

Features of UPVC Ball Valves

- High Resistant to Corrosion by acids, alkalis, and corrosive media

- Used in wide range of applications

- Lightweight compared to metal valves

- Less Expensive than metal valves

- Minimal Maintenance and easy to clean

Material Composition

UPVC ball valves are made from rigid PVC material that has not been plasticized, making them resistant to chemical corrosion and high temperatures.

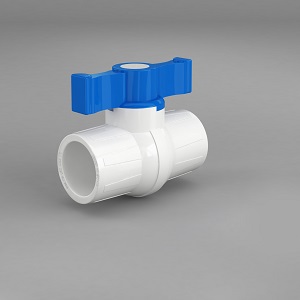

Design

UPVC ball valves consist of a spherical closure mechanism with a bore that allows fluid flow when aligned with the pipe and blocks flow when turned perpendicular to it.

The ball valve typically has a handle or lever that controls the rotation of the ball. When the handle is turned 90 degrees, the valve is fully open and when it turned another 90 degrees valve is getting fully closed.

Applications

- Residential, Commercial, industrial water supply systems

- Chemical Processing Plants

- Irrigation or Agriculture Systems

- Swimming Pool Plumbing Systems

Sizes

- 1/2 inch

- 2 inch

- 3/4 inch

- 1¼ Inch

- 1½ Inch

Pressure Ratings

- PN10 to PN16 (10 to 16 bar)

- May Change as per manufacturer

End Connections

- Solvent Cement Sockets

- Threaded Ends (Male or Female)

- Flanged Ends

- Compression Fittings

Standards

- ASTM, ANSI, BS, DIN, and ISO standards

Accessories

- Locking Devices

- Extension Spindles

- Pneumatic actuators

- Electric actuators

Manufacturer’s Instructions

It’s essential to follow the manufacturer’s instructions for installation, operation, and maintenance to ensure optimal performance and longevity of the UPVC ball valve.

Temperature Range

- 0°C to 60°C (32°F to 140°F)

- Also depends on manufacturer

Chemical Compatibility

While UPVC offers excellent resistance to many chemicals and it is very much essential to verify compatibility with the specific chemicals present in the intended application. Certain chemicals or extreme pH levels may still degrade or damage UPVC over time.

Sealing Mechanism

- Elastomeric Seals

- EPDM

- Viton

- PTFE (Teflon) seals

Flow Characteristics

- Full Port

- Reduced Port

Actuation Options

- Pneumatic

- Electric

- Hydraulic

- Automated

Pressure Drop

Evaluate the pressure drop across the UPVC ball valve, especially in systems with limited pressure headroom. Understanding the pressure drop helps ensure that the valve selection does not significantly affect system performance or efficiency.

Certifications and Compliance

- NSF/ANSI 61 for drinking water applications

- ATEX certification for use in potentially explosive atmospheres

Installation Considerations

- Alignment

- Adequate Support

- Appropriate Sealing Techniques

Maintenance Requirements

- periodic inspection and maintenance

- Proper Check of issues such as wear, damage, or buildup of debris

- Manufacturer recommendations for maintenance intervals and procedures to ensure continued functionality.

Environmental Impact

- Recyclability

- Minimal environmental footprints

- Sustainability goals

- Regulatory requirements

This are some of the points one should cover while manufacturing as well as buying of this UPVC Ball valves. We hope enough information is provided on the topic. If you have any questions please contact us.